Company Overviewbuisiness

Company Overview

Providing high-Quality resources

We handle various silica sands product as raw material for glass and construction material, as well for quartz, feldspar, and resin fillers. Through diligent quality control and make use of the technology we have cultivated over the years, we have earned high praise from our customers.

In addition, we always make appropriate proposals to meet the diverse needs of our customers and solve their challenges.

Our Product

-

Raw materials for glass ceramics industry

We utilize cutting-edge production technology to deliver high-quality products with low impurities.

Silica sand and feldspar, which are the main raw materials for glass, have received high praise from our customers in various fields. This is due to our accumulated technology know how of grinding, classification, benificiation, and our quality control system. We carefully select high-quality raw materials and provide them in various industries.

- Usage

- Silica sand, feldspar, dolomite: display glass, LCD glass, automotive glass, Architectural Glass, bottle glass, special glass

-

Izu silica quartz/rock

Izu quartz produced from the Izu quartz mine located in Ugusu, Nishiizu-Town, Kamo-District, Shizuoka-Prefecture. (west coast of the Izu Peninsula)

The Izu Quartzite Mine is a quartz deposit formed by hydrothermal alteration. The struture is characterized porous and easy to grind, having a uniform quartz crystal grain size, and having good reaction with quartz particles.

- Usage

- Izu silica grain: Pesticide carrier

- Izu special powder: thermal insulation, refractories, environment

-

Silica

Using our own proprietary silica quartz evaluation technology and quality control system, we are able to select and manufacture only high-quality silica stone throughout quality control from mining,grinding, classification, and shipment.

- Usage

- ALC (Autoclaved Lightweight Concrete), construction materials, civil engineering, cement

-

Silica sand

We’re capable to process quality packaging and transport according to the application and propose the optimal silica sand using our technology.

- Usage

- Silica sand for construction and industrial products: mortar, environment, biomass

- Sports sand: bunker sand, topsoil for golf course, artificial turf, beach sand, House racing track

-

Functional filler

Due to its high heat resistance and non-flammability, it is widely used as a material for improving fire resistance and increasing strength of base materials.

- Usage

- Mica: Various building materials such as exterior materials, plastics, paints, rubber, cosmetics, etc.

- Silica powder: glazes, exterior materials, paints, abrasives, Glass fiber

-

Environment/recycling business

Housing/construction materials[ALC recycled material]

It is an environmentally friendly recycled material that utilizes the functions of ALC.[Glass roof tiles]

The glass tile lighting system is a new skylight system that roofs with glass tiles, and consists of glass tiles, base units, and other parts. We have a lineup of 5 types of tiles, which can be freely constructed up to atypical shapes such as strip-shaped design, large area, and L-shaped, and have the same shape as ceramic clay tiles.- Usage

- ALC recycled material: Rooftop greening, soluble silicate fertilizer, soil for cultivation, humidity regulator, water retention material

- Glass roof tiles: Housing materials

Quality management

To provide safe, secure, and high-quality products at all times

We have established strict guidelines and a thorough quality control system.

Main Analysis Equipment

-

Wavelength dispersive X-ray analyzer (XRF)

Shimadzu XRF-1800

By irradiating a sample with X-rays, the type and amount of elements that make up the substance can be identified from the wavelength and intensity of fluorescent X-rays that are generated, and multiple elements can be analyzed simultaneously and quickly. Equipped with 5 types of spectroscopic crystals, it is possible to analyze from heavy elements to light elements (boron).

-

ICP emission spectrometer

Shimadzu ICPS-7510

Evaporative vaporization is excited by spraying a solution sample into the plasma, qualitative from the wavelength of the obtained element-specific spectrum, and quantification is performed from the emission intensity. ICP can accurately measure many elements, down to trace components.

-

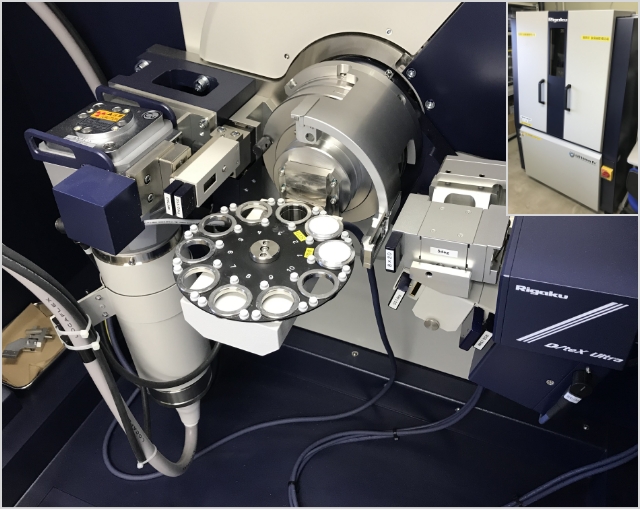

X-ray diffraction analyzer (XRD)

Rigaku Multi Flex

This device irradiates a sample with X-rays and identifies the sample composition from the shape of the obtained X-ray spectrum. Equipped with comprehensive powder X-ray diffraction pattern analysis software, it can be quickly identified from an extensive database.

-

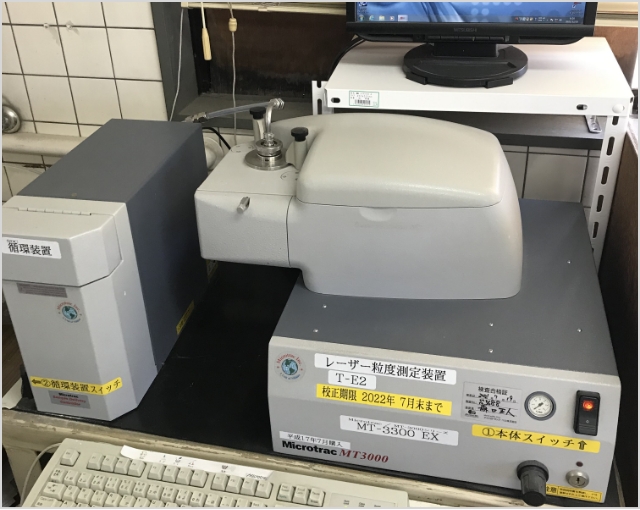

Laser diffraction scattering type particle size distribution analyzer

Nikkiso MT3300EX II

By placing a powder sample in a solution and irradiating it with laser light, the particle size can be measured from the scattered light, and the particle size distribution can be measured from the intensity distribution. Particle size from 0.02 to 1400 μm can be measured.

-

Sample pretreatment device

NIKKISO DESKTOP HIGH FREQUENCY BEAD SAMPLER

X-ray fluorescence sample preparation equipment. Normally, samples that have been grinded and pressure-molded are analyzed, but this device can improve the accuracy of analysis by melting and vitrifying samples that cannot be analyzed accurately due to differences in crystal structure, etc.